// Technology R & D

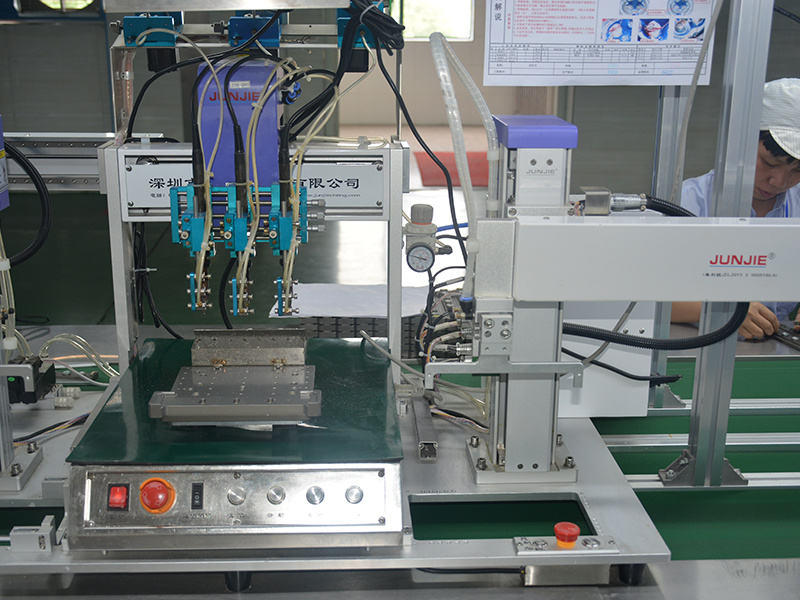

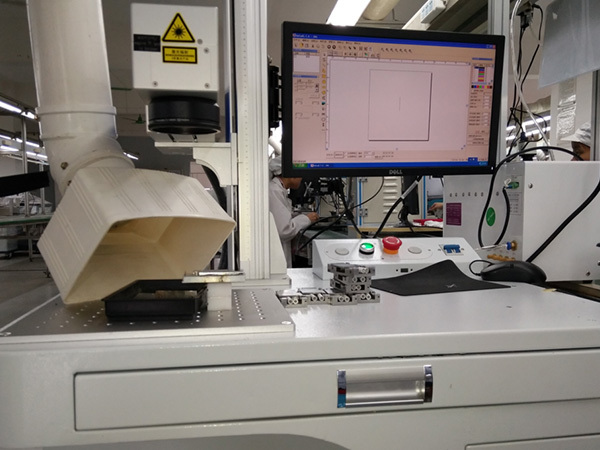

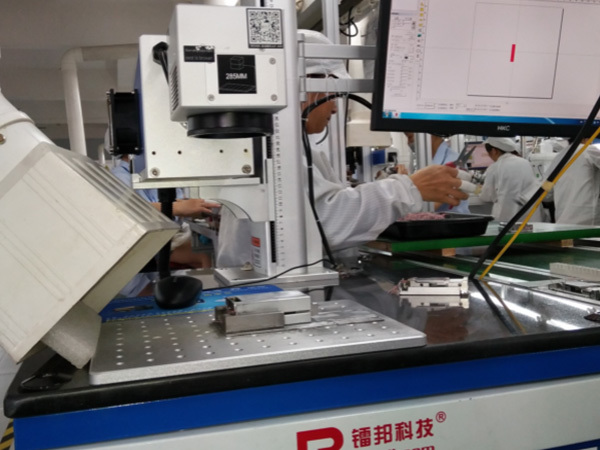

Accelerate the construction of industrial 4.0 production

The R & D department was established in 1993, customer and market-oriented, aiming to develop new headphones, new speakers, data cables, mini speakers and peripheral products of multimedia equipment, etc., which can not only meet the design requirements of customers, but also have independent intellectual property rights. Research and development, has achieved a number of intellectual property achievements, and the existing 30 people have many years of experience in the headset industry, is a professional development team with rich experience and strong development ability.

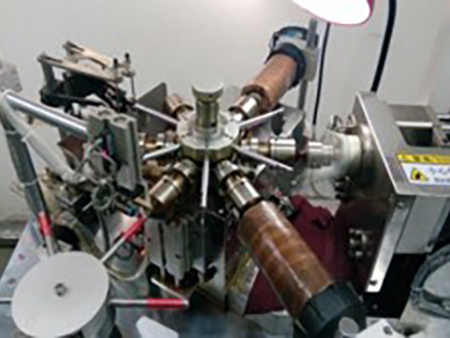

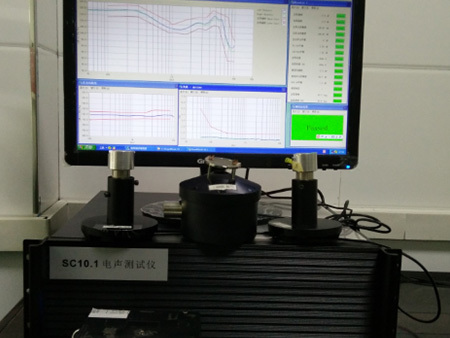

In order to meet the needs of different customers, the engineering department has set up a number of project teams, each of which is controlled by professional engineers. The project leader has rich project organization ability and coordination ability in technical research, and is equipped with full-time technical personnel such as ID design, mold design, horn development, PCB design, tooling design, sample production, technical document production, testing and testing to assist in development; we have purchased professional electroacoustic testing instruments such as full-elimination silent room, B & K analog head, SOUNDCHECK, sunshine and many other experimental equipment to ensure the rationality of the design and the quality of the products.

Established R&D

Project Team

R & D Engineer

Certificate

// Mold manufacturing

Professional mold workshop

The company has a professional mold production workshop, with the ability from structural design to mold manufacturing, from wire extrusion, plastic parts molding, horn manufacturing to finished product assembly complete earphone production process.

Mold manufacturing capacity:

Mold design → 3D → parting → programming → computer gong → fast wire running → slow wire running → spark machine → high light saving → mold

Mold opening cycle:

7-15 days

CNC machining center

Dimon mirror spark machine

Mold workshop

spark machine

Equipment display

Quality Assurance

The company has always adhered to the quality of survival, cost competition, reputation and development, management and efficiency model.

Management System

The company has always adhered to the model of survival by quality, competition by cost, development by reputation, and efficiency by management. It has passed the ISO9001/ISO14001/ISO45001/QC080000 management system certification. All products comply with RoHS, HF and REACH environmental protection standards.

environmental system

☉All-in-one green supply chain management

☉Full green system management

☉Implementation of greenhouse gas inventory and implementation of energy conservation and carbon reduction plans